Todos os Produtos

-

Bobina de tira de alumínio

-

Bobina de alumínio revestida da cor

-

Rolo da folha de alumínio

-

Placa de folha de alumínio

-

Disco de alumínio do círculo

-

Película de poliéster laminada em folha de alumínio

-

Placa quadriculado de alumínio

-

Diamond Plate Sheet de alumínio

-

Folha de alumínio gravada

-

Folha de alumínio anodizada

-

Folha de alumínio do espelho

-

Recipiente de folha de alumínio

-

Lancheira da folha de alumínio

-

Grelha de churrasco descartável

-

MartinA primeira vez que nós cooperamos com o alumínio de Yongsheng, nós encontramo-lo muito fácil, porque o prazo de entrega dos bens era muito rápido, e o diretor empresarial era igualmente muito profissional. Ajudou-me a resolver alguns problemas técnicos. Os bens foram recebidos em 2021.1.20 e na qualidade dos bens muito bons!

MartinA primeira vez que nós cooperamos com o alumínio de Yongsheng, nós encontramo-lo muito fácil, porque o prazo de entrega dos bens era muito rápido, e o diretor empresarial era igualmente muito profissional. Ajudou-me a resolver alguns problemas técnicos. Os bens foram recebidos em 2021.1.20 e na qualidade dos bens muito bons! -

Alice SuNossos empresa e alumínio de Yongsheng têm cooperado por quase três anos. Nós visitamos a fábrica, Yongsheng é um fornecedor material de alumínio profissional, nós temos comprado as tiras de alumínio em sua fábrica, e manteremos a cooperação a longo prazo.

Alice SuNossos empresa e alumínio de Yongsheng têm cooperado por quase três anos. Nós visitamos a fábrica, Yongsheng é um fornecedor material de alumínio profissional, nós temos comprado as tiras de alumínio em sua fábrica, e manteremos a cooperação a longo prazo. -

ZoeyNós compramos o círculo de alumínio do alumínio de Yongsheng e enviamo-los a Gana. Nós mantivemos um relacionamento tão cooperativo por dois anos, e nós temos que enviar cada mês. Em processo da cooperação, cada relação é muito eficiente, e o gestor de conta ajudar-nos-á a resolver rapidamente problemas. Nós estamos muito felizes encontrar um fornecedor seguro.

ZoeyNós compramos o círculo de alumínio do alumínio de Yongsheng e enviamo-los a Gana. Nós mantivemos um relacionamento tão cooperativo por dois anos, e nós temos que enviar cada mês. Em processo da cooperação, cada relação é muito eficiente, e o gestor de conta ajudar-nos-á a resolver rapidamente problemas. Nós estamos muito felizes encontrar um fornecedor seguro. -

Amin MazlumNós compramos um total de quase 500 toneladas de bobinas de alumínio gravadas da cor do alumínio de Yongsheng. A qualidade foi estável e o prazo de entrega é rápido. Meus clientes são satisfeitos muito com meus produtos. Nós continuaremos a cooperar com o alumínio de Yongsheng.

Amin MazlumNós compramos um total de quase 500 toneladas de bobinas de alumínio gravadas da cor do alumínio de Yongsheng. A qualidade foi estável e o prazo de entrega é rápido. Meus clientes são satisfeitos muito com meus produtos. Nós continuaremos a cooperar com o alumínio de Yongsheng.

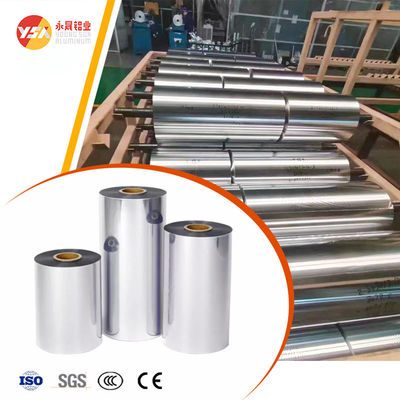

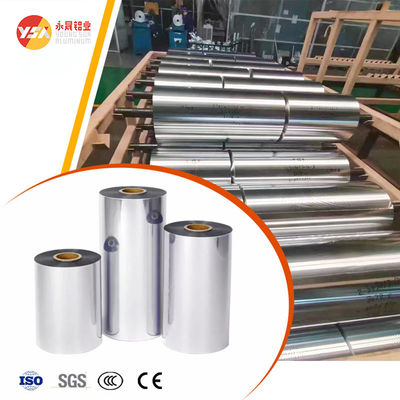

8011 Household Aluminum Foil Pack Bag Foil Aluminum Foil Jumbo Roll Food Usage

| Lugar de origem | Província de Henan, China |

|---|---|

| Marca | YONGSHENG |

| Certificação | ISO, RoHS, FDA |

| Número do modelo | 1235, 8011, 8079, etc. |

| Quantidade de ordem mínima | 1 tonelada |

| Preço | 2950-3350 USD/Ton |

| Detalhes da embalagem | Embalagem padrão do mar |

| Tempo de entrega | 7-25 dias após a confirmação do pedido |

| Termos de pagamento | L/c, d/a, d/p, t/t |

| Habilidade da fonte | 5000 toneladas por mês |

Detalhes do produto

| Liga | 1235, 1145, 8011, 8021, 8079, etc | Temperamento | O, H18 |

|---|---|---|---|

| Grossura | 0,004-0,2mm | Largura | 200- 1700mm |

| Comprimento | Requisito do cliente | Diâmetro interno | 75/150 mm |

| Usar | Embalagem, alimentos para a construção de saúde | Padrão | ASTMB209, EN573-1S |

| Porta | Qingdao, Xangai, Tianjin | Amostra | livre |

| Destacar | Rolo da folha de alumínio do agregado familiar,jumbo aluminum foil pack,Folha de alumínio de grau alimentar |

||

Descrição de produto

8011 Folha de alumínio para uso doméstico

Rolos de papel de alumínio de qualidade alimentícia premium concebidos para aplicações domésticas e comerciais de embalagens alimentares.

Características do produto

Características fundamentais

- Fabricados a partir de liga de alumínio primário com recozimento e desinfecção a alta temperatura

- A camada superficial densa de óxido garante a estabilidade química e a segurança dos alimentos

- Inibe o crescimento bacteriano e não contém substâncias nocivas

- Ampla gama de resistência a temperaturas (-20°C a 250°C)

- Estrutura molecular estável adequada para esterilização a altas temperaturas

- Excelentes propriedades de barreira contra luz e gases

- Preserva o sabor dos alimentos, bloqueia a umidade, prolonga a vida útil

- Muito reciclável com menor consumo de energia durante a regeneração

- Brilho metálico brilhante compatível com impressão e tratamentos de superfície

- Leve, fácil de transportar e resistente a rachaduras quando dobrado

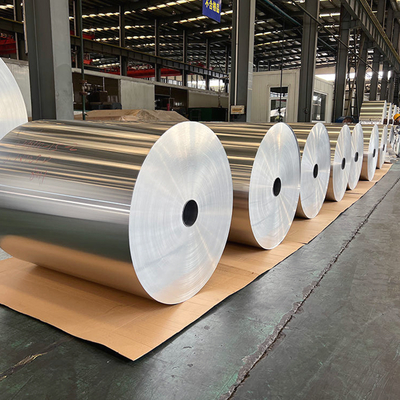

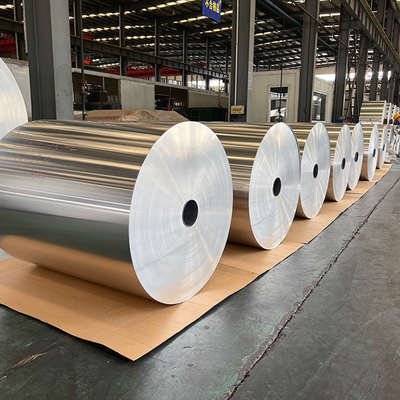

Processo de produção de folhas de alumínio

O processo de fabrico começa com o aquecimento dos lingotes a 400-500°C e a laminação a quente até aproximadamente 3 mm de espessura.seguido de recozimento a 350-450°C para suavizaçãoA folha é então cortada para largura padrão, inspeccionada para qualidade e embalada para envio.

Vantagens da fábrica Yongsheng

Produção em grande escala:Satisfazer as exigências substanciais do mercado, ao mesmo tempo que otimiza os custos

Tecnologia avançada:Equipa profissional que desenvolve novos processos para melhorar o desempenho

Garantia da qualidade:Sistema de controlo abrangente conforme com as normas ISO e FDA

Serviços de personalização:Soluções personalizadas para composição, espessura, largura e tratamentos de superfície de ligas

Tecnologia avançada:Equipa profissional que desenvolve novos processos para melhorar o desempenho

Garantia da qualidade:Sistema de controlo abrangente conforme com as normas ISO e FDA

Serviços de personalização:Soluções personalizadas para composição, espessura, largura e tratamentos de superfície de ligas

Especificações do produto

| Produto | Alcatrão | Temperatura | Largura (mm) | Espessura (mm) | Aplicações |

|---|---|---|---|---|---|

| Folha farmacêutica | 8011 8021 | O-H18 | 100-1600 | 0.01-0.2 | Embalagens de cápsulas farmacêuticas, sacos |

| Folha de concha de bateria | 8021 8079 1235 | O | 100-1600 | 0.015-0.055 | Folha de embalagem de bateria |

| Folha de condensador de elétrodo | 1070 3003 1100A | H18 | 100-1600 | 0.016-0.4 | Componentes eletrónicos |

| Folha Tate | 1060 8011 1235 | O-H18 | 100-1600 | 0.016-0.4 | Indústrias de refrigeração, automóveis e electrónica |

| Folha de embalagem de alimentos | 1060 3003 8011 1100 3004 8021 | H24 H22 H18 O | 300 a 1100 | 0.01-0.2 | Aplicações de embalagens alimentares |

| Folha de vedação térmica | 8011 8079 1235 | O/HO | 100-1600 | 0.025-0.1 | Embalagens de géneros alimentícios e farmacêuticos |

Comparação de desempenho das principais ligas

| Grau de liga | Composição principal | Força | Duxtilidade | Resistência à corrosão | Aplicação básica |

|---|---|---|---|---|---|

| 1235 | 99.35% Al + Si, Fe | Baixo | Extremamente elevado | Alto | Embalagens flexíveis para alimentos e medicamentos, papel de folha de alumínio |

| 1145 | 990,45% Al + Si, Fe | Baixo | Extremamente elevado | Alto | Embalagens de elevada flexibilidade |

| 8011 | Al + 0,7-1,1% Fe + 0,5-0,9% Si | Médio | Médio | Alto | Caixa de refeições, blister de medicamentos, junta de tampa do frasco |

| 8021 | Al + 0,8-1,2% Fe + 0,5-0,9% Si | Médio | Médio | Alto | Embalagens ultrafinas |

| 3003 | Al + 1,0-1,5% Mn | Alto | Médio | Alto | Embalagens industriais, filme de baterias de lítio |

Imagens do produto

Aplicações do produto

Produtos recomendados